Thruster Brake: Reliable and High-Performance Braking Solutions by CMK Electro Power

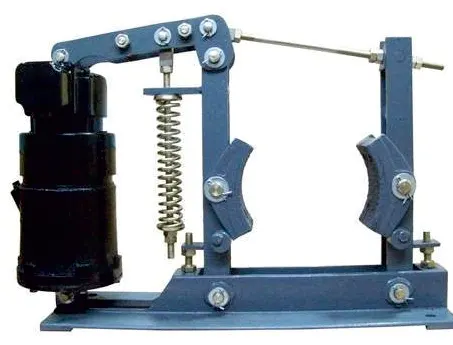

Electro Hydraulic Thruster Brake

Our mill duty Thruster Brakes are suitable for 440 Volts, 3 Phase A.C. supply for a wide range of drum sizes, from 100mm to 600 mm dia. Higher sizes can also be supplied against specific requirements. The brake is applied by the tension of the compressed springs mounted vertically between the thruster and brake lever. The thruster rods are connected with the brake by means of an angle lever As the piston travels upwards the angle lever tums, pushes the brake rod and compresses the brake spring Simultaneously, the brake lever on the other side of the wheel (Brake Drum) is retracted.

Our crane brakes are designed to deliver robust and reliable performance for EOT cranes, overhead cranes, gantry cranes, and other industrial lifting equipment. Built to meet the highest safety standards, our EOT crane brakes and overhead crane brakes ensure smooth and controlled operations, even under heavy loads.

We provide advanced solutions such as electromagnetic brake for crane, crane magnetic disc brake, and brake crane systems, all engineered for excellent wear resistance, quick response, and minimal maintenance. Our range also includes thruster brakes, hydraulic thruster brakes, and heavy-duty options like the 18 kg thruster and 34 kg thruster, ensuring compatibility with diverse industrial environments.

Trusted for durability and safety, our crane brake solutions enhance efficiency, reduce downtime, and guarantee reliable operation for modern crane applications.

We provide advanced solutions such as electromagnetic brake for crane, crane magnetic disc brake, and brake crane systems, all engineered for excellent wear resistance, quick response, and minimal maintenance. Our range also includes thruster brakes, hydraulic thruster brakes, and heavy-duty options like the 18 kg thruster and 34 kg thruster, ensuring compatibility with diverse industrial environments.

Trusted for durability and safety, our crane brake solutions enhance efficiency, reduce downtime, and guarantee reliable operation for modern crane applications.

| Brake Model | Brake Drum Dia mm | Brake Tourqe | Brake Model | Brake Drum He mm | Brake Tourqe | ||

|---|---|---|---|---|---|---|---|

| kg-m | N-m | kg-m | N-m | ||||

| MDT-100-18 | 100 | 6 | 60 | MDT-400-46 | 400 | 90 | 900 |

| MDT-150-18 | 150 | 9 | 90 | MDT-400-68 | 400 | 110 | 1100 |

| MDT-160-18 | 160 | 9 | 90 | MDT-500-48 | 500 | 190 | 1900 |

| MDT-200-18 | 200 | 20 | 200 | MDT-500-68 | 500 | 290 | 2900 |

| MDT-250-18 | 250 | 35 | 350 | MDT-500-114 | 500 | 485 | 4580 |

| MDT-250-34 | 250 | 42 | 420 | MDT-600-68 | 600 | 350 | 3500 |

| MDT-300-34 | 300 | 62 | 620 | MDT-600-114 | 600 | 580 | 5800 |

Electro Hydraulic Thrusters

Electro-Hydraulic Thruster A compact 60watt, 2800 rpm. 415v/50Hz/3-ph, non-ventilated motor is directly mounted on the top of a moving aluminum piston. A cast iron tank containing the brake fluid actcs as the cylinder, the piston separates the cylinder into high pressure and low pressure chambers. The bi directional impeller is mounted directly on the motor shaft. The upper clevis in integral with the top and shield of the motor and the lower clevis is on the bottom of the tank cover.

| Model No. | Rated Thrust (kg) | Output Stroke (S) | Input Watts |

|---|---|---|---|

| EHT-18K | 18 | 51 | 90 |

| EHT-34K | 34 | 51 | 150 |

| EHT-45K | 45 | 51 | 180 |

| EHT-68K | 68 | 76 | 200 |

| EHT-113K | 113 | 76 | 250 |

| EHT-225K | 225 | 127 | 420 |

| EHT-295K | 295 | 127 | 580 |

Brake Shoe Liner

CMK Manufacturing a wide range of brake linings, which is of excellent quality. These are made of soft but tough heat resistant material with a high coefficient of dynamic friction we offer rubber brake linings, asbestos brake linings. automotive brake linings, which are made using a unique blend of ingredients such as asbestos, friction dust, resins etc. These products are used in industrial brake application.

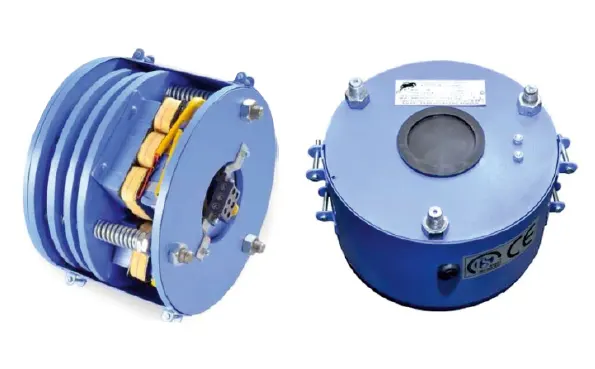

AC Failsafe Electromagnetic Disc Brake

Very compact and modern in design, Foundation is not necessary as they are directly mounted on non-driving end shaft of the motor. It consist of liner prices (Brake Disc) with square hole at the center One corresponding piece of square hub is supplied with the brake. This hub is keyed to the motor shaft and the finer plate is free on this hut Normally Liner plate is gripped between two discs with the help of spring pressure they work on 230 / 415 VAC When the current is supplied to the brake, one disc is attracted by electromagnet against spring pressure and the liner plate os released. Thus the brake is ‘off’. Once the brake is set it dose not required adjustment or maintenance When the liner plates wears with the use then only air gap is to be maintained periodically An arrangement to release the brake manually could be provided on request

| Range | Tech.Data | |||

|---|---|---|---|---|

| T Kg. m | VA | Sq. Hub M | N | |

| EMD-125 | 0.2 | 80 | 28.0X28.0 | 25 |

| EMD-150 | 1.1 | 80 | 38.1X38.1 | 25 |

| EMD-150X | 2.2 | 80 | 38.1X38.1 | 45 |

| EMD-190 | 2.5 | 165 | 38.1X38.1 | 28 |

| EMD-190X | 4.5 | 165 | 38.1X38.1 | 45 |

| EMD-235 | 4.0 | 205 | 50X50 | 28 |

| EMD-235X | 6.0 | 205 | 50X50 | 45 |

| EMD-290 | 5.5 | 275 | 50X50 | 30 |

| EMD-290X | 11 | 275 | 60X60 | 45 |

| EMD-290XX | 14 | 275 | 60X60 | 60 |

Electromagnetic Dc Brake

Our DC Brake has a name as absolute reliable brake for use in almost every application. As standard, this brake is available in 10 different sizes for static or dynamic braking with re- settable air gap design. Due to several variations and options, this brake series is preferred by motor manufactures for universal use.

Benefits :

- manual hand release

- micro switch or inductive sensor to

- monitor brake function or wear limit

- friction plate or adopter flange

- taped bores for tacho maunting

- dust protection ring

- temperature feeler

- rest period heating

- low noise version

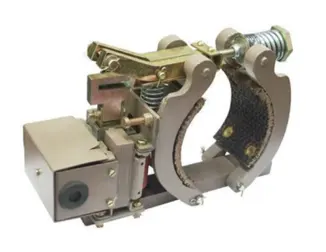

Ac Solenoid Brake

AC Solenoid Brake that are suitable for AC supply up to 440 volts, and are available for a wide range of drum sizes from 100mm to 380mm Dia. We stand in the midst of prominent electromagnetic brakes suppliers based in India

AC Brakes

- 4" Dia / 5.5" Dia / 7" Dia

Solenoids

- Type : SLB - 25 mm stroke length

- Type : SLD - 31.4 mm stroke length

Features

- Class F- insulation of the coil

- Continuous & intermittent duty

- Long life & ease of maintenance

- Ideally suited for applications such as Cranes, Hoists, Machines, Valves,Conveyers

Ac Solenoid Brake - Type-S

| Type of Brake | Wheel Inch | Max. Torque | Duty | ||

|---|---|---|---|---|---|

| Inch | MM | Lb. ft | Nm | ||

| S-4 | 4 | 101.6 | 10 | 13.6 | Continuos |

| S-5 | 5.5 | 139.7 | 25 35 | 34.0 48.0 | Continuos intermittent |

| S-7 | 7 | 177.8 | 50 75 | 68.0 102.0 | Continuos intermittent |

Fill the contact Form and we will contact you shortly.

Please provide your details in the form below, and our team will get back to you as soon as possible to assist with your query.

FAQs for Crane Brakes (EOT & Overhead Cranes)

What is a crane brake and why is it important?

A crane brake is a safety component that controls the motion of EOT cranes, overhead cranes, gantry cranes, and industrial lifting equipment. It ensures smooth stopping, prevents accidents, and maintains safe, reliable operations under heavy loads.

What types of crane brakes do you offer?

We provide a wide range of crane brakes, including:

EOT crane brakes & overhead crane brakes

Electromagnetic brake for cranes

Crane magnetic disc brakes

Thruster brakes & hydraulic thruster brakes

Heavy-duty 18 kg thruster & 34 kg thruster brake systems

How does an electromagnetic brake for crane work?

An electromagnetic brake for cranes uses a magnetic field to apply force on the brake disc, ensuring quick response, precise stopping, and minimal maintenance. It is widely used in modern crane applications for reliability and efficiency.

What are thruster brakes in cranes?

Thruster brakes are powerful braking systems driven by an electro-hydraulic thruster. They are ideal for heavy-duty EOT cranes and overhead cranes, ensuring smooth operation, wear resistance, and enhanced safety.

What is the difference between hydraulic thruster brakes and electromagnetic brakes?

Hydraulic thruster brakes use fluid pressure for smooth, gradual braking in heavy-duty operations.

Electromagnetic brakes rely on magnetic force for instant braking, quick response, and minimal wear.

Which crane brake is best for heavy-duty applications?

For heavy-duty lifting and industrial environments, thruster brakes (18 kg & 34 kg thrusters) and hydraulic thruster brakes are the best options, offering durability, strong braking force, and long service life.

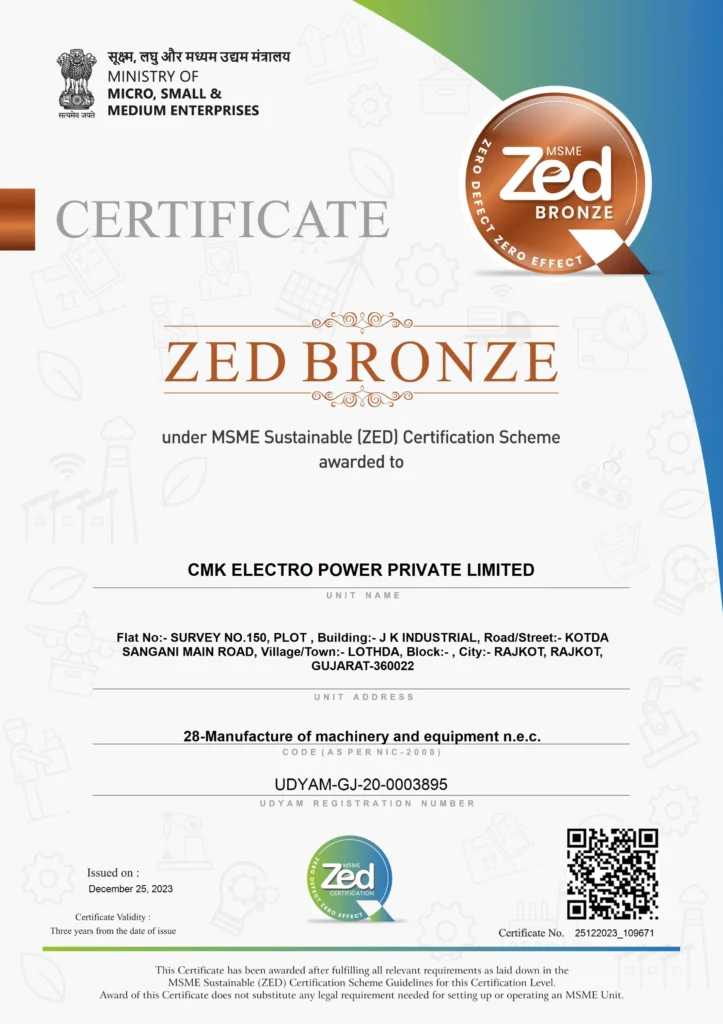

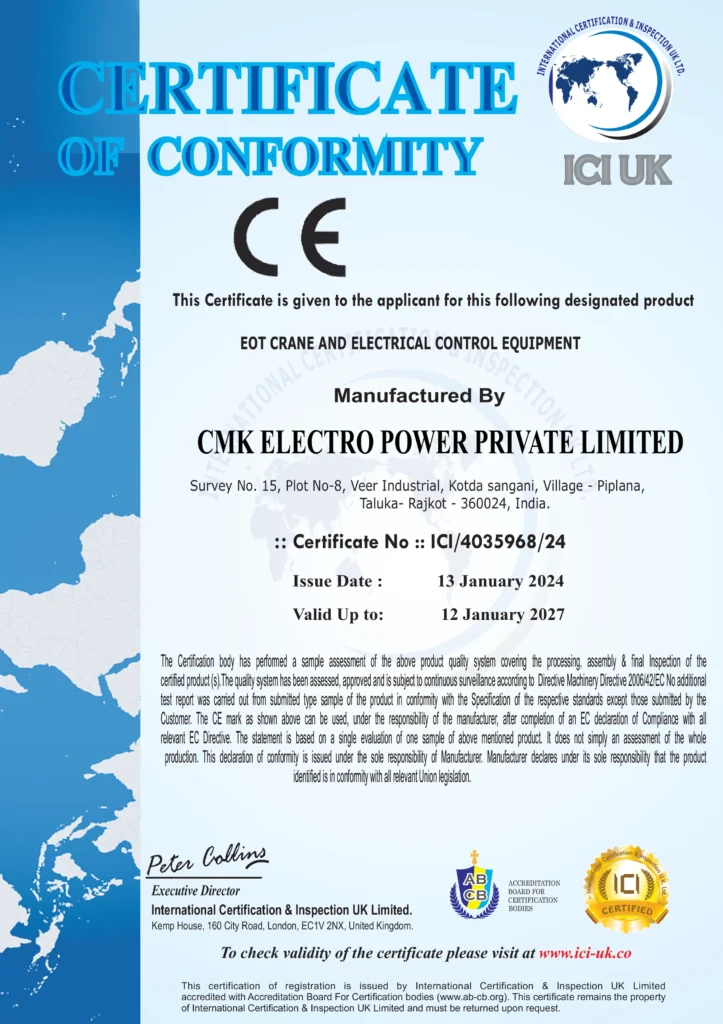

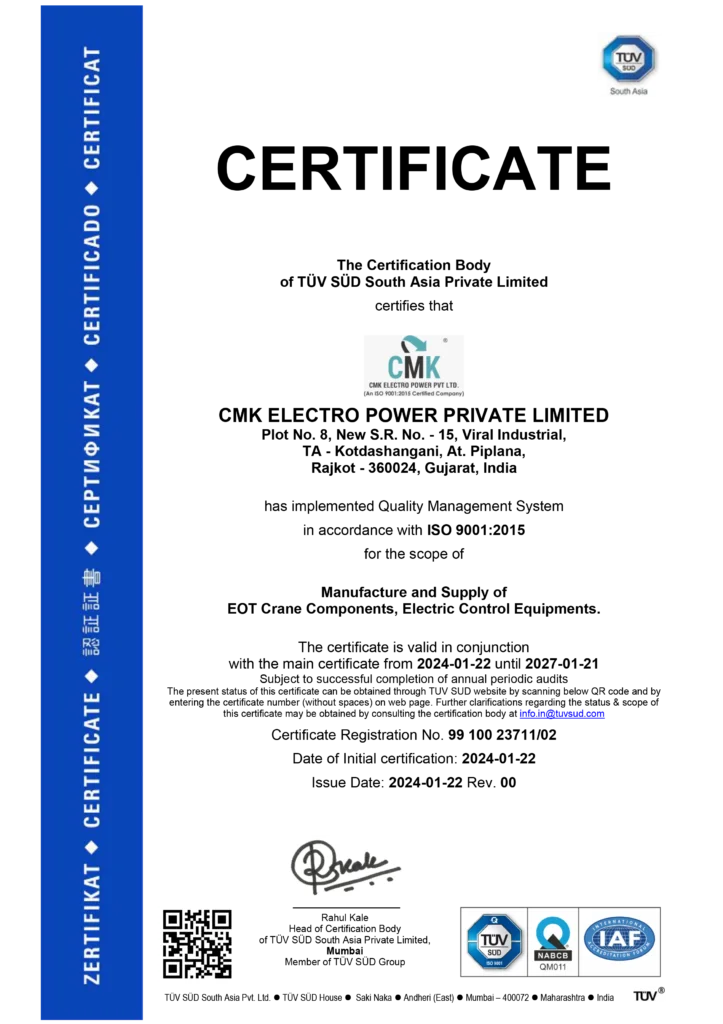

Are your crane brakes compliant with international safety standards?

Yes. All our crane brakes, thruster brakes, and electromagnetic brakes are designed to meet strict international safety and performance standards, ensuring reliable operation and operator safety.

What are the benefits of using your EOT and overhead crane brakes?

Robust performance under heavy loads

Quick response time

Low maintenance & high wear resistance

Enhanced safety & efficiency

Long-lasting durability

Do you supply spare parts for crane brakes?

Yes, we provide crane brake spare parts and accessories including brake liners, discs, coils, and thruster components, ensuring smooth operation and easy maintenance.

In which industries are your crane brakes used?

Our crane brake systems are trusted across steel plants, power plants, manufacturing units, shipyards, construction sites, warehouses, and material handling industries.