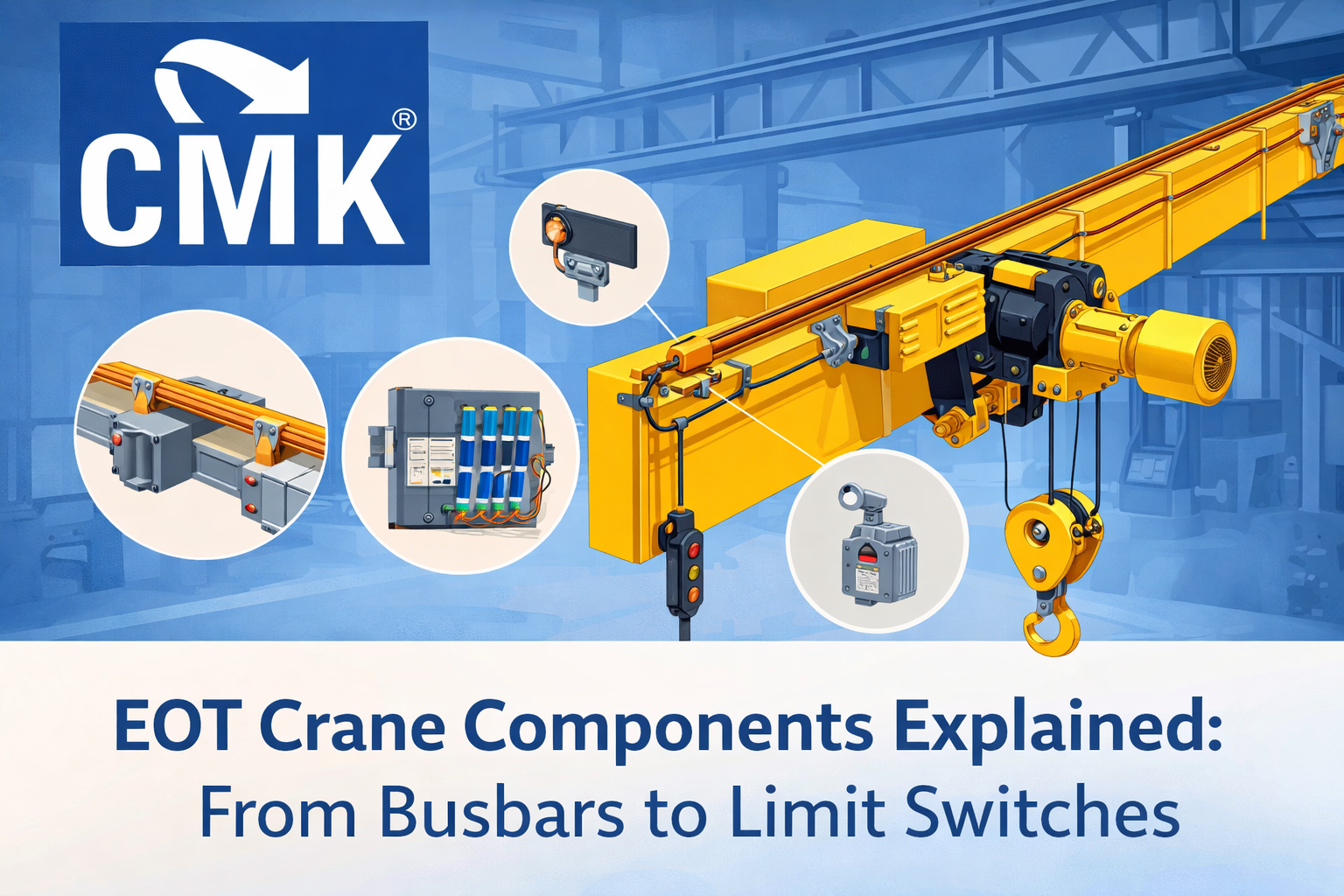

In every industrial plant, EOT cranes move silently above the workforce — lifting, transferring, and positioning materials that keep production in motion. Their performance looks effortless, but behind this smooth operation lies an ecosystem of carefully engineered parts. From power transmission to safety control, these EOT crane components determine how reliably and safely a crane performs its job.

In sectors like steel, chemicals, power, automotive and logistics, even the smallest component can influence uptime, load accuracy, and operational safety. This is why choosing the right crane components is just as vital as choosing the crane itself. For manufacturers and plant operators seeking high-performance, long life and industry-ready components, CMK India has become a trusted name — known for delivering systems designed to withstand real-world industrial conditions.

Understanding the Purpose of EOT Crane Components

An EOT crane is not just a machine — it is a system built from multiple subsystems. Power transmission, trolley movement, hoisting control, safety mechanisms, and operator communication all depend on distinct components designed for specific functions. When these components work together seamlessly, cranes deliver smooth and consistent performance. When even one fails, operations can come to a halt.

Let’s explore these components from the ground up.

1. Busbar Systems: Delivering Safe, Continuous Power

The busbar system is one of the most crucial EOT crane components because it provides the crane with uninterrupted electrical power. Unlike traditional cable-based power supply, busbars offer consistent performance, less wear and tear, and enhanced safety.

Different types of busbars serve different environments:

- Shrouded DSL busbars for general industrial use

- Insulated busbars for high-temperature or corrosive zones

- Box systems or multipolar systems used in heavy-duty cranes

A well-designed busbar ensures strong electrical contact, resistance to harsh conditions, and reliable long-term performance.

2. Current Collectors: The Bridge Between Power and Motion

A busbar alone cannot energize a crane — it requires a current collector to pick up electricity as the crane moves. This sliding contact system must maintain stable current transfer under vibration, long travel distances, and continuous operational cycles.

A good current collector ensures:

- Minimal voltage drop

- Low wear on the busbar

- Stable power pickup even in dusty or hot environments

This makes it one of the most critical moving components in crane electrification.

3. Festoon Systems: Smart Cable Management

Festoon systems manage the movement of control and power cables along the crane’s path. By guiding cables neatly through trolleys and tracks, festoons prevent tangling, cable stretching, or accidental snagging.

Their benefits include:

- Longer cable life

- Smooth, friction-free motion

- Safe movement of cables during trolley travel

Festoon systems are essential for maintaining electrical integrity during crane operation.

4. Limit Switches: Safety Controllers of Crane Motion

Limit switches act as the crane’s safety boundary regulators. They stop the crane from exceeding its safe travel limits — whether it is the hoist rising too high, the trolley reaching the beam end, or the crane approaching an end stop.

Common types include:

- Rotary limit switches for hoist motion

- Gravity and lever-operated switches for directional limits

- Heavy-duty safety switches for large industrial cranes

These switches protect both equipment and personnel, making them indispensable in every crane system.

5. Pendant Stations & Controls: The Operator’s Command Center

Operators rely on pendant stations or remote control systems to guide crane movement. These controls must be clear, responsive, and designed for industrial safety.

Features of reliable crane control systems include:

- Ergonomic, fatigue-free design

- Clearly defined hoist and travel buttons

- High resistance to impact, vibration, and dust

Accurate control systems ensure smooth, safe crane operation even under demanding conditions.

6. Mechanical Components: The Strength Behind Crane Performance

Mechanical parts support the crane’s load-bearing and movement functions. Components such as rope drums, gears, couplings, rail clamps, and brake systems require high structural integrity because they endure massive loads and continuous duty cycles.

Well-engineered mechanical components ensure:

- Smooth hoisting

- Reliable braking

- Long-life structural performance

These parts define the crane’s operational strength and durability.

Why High-Quality EOT Crane Components Matter

Every component in an EOT crane influences uptime, safety, and accuracy. When components are built with quality materials and industry-focused engineering, the crane becomes more reliable and can be easily maintained. Poor-quality components, in contrast, cause operational delays, frequent breakdowns and safety hazards.

For plants that operate cranes in critical or hazardous environments, investing in reliable components is not a luxury — it is a a necessity.

Where CMK India Creates Value in the Crane Ecosystem

As one of India’s well-respected manufacturers of eot crane components, CMK India supports crane OEMs, EPC contractors and industrial plants with components built specifically for demanding environments. Their busbars, current collectors, limit switches, festoon systems and mechanical assemblies are all designed in a way that is precise, durable and safe.

By supplying components that withstand real industrial challenges, CMK India plays a crucial role in keeping cranes safe, efficient, and reliable across sectors.

Conclusion

EOT cranes power the backbone of manufacturing and heavy industry — but their true performance depends on the quality of their components. From busbar systems that energize the crane to limit switches that prevent unsafe movement, each part contributes to safety, efficiency, and operational continuity.

Understanding these eot crane components helps industries choose better, maintain better, and operate with greater confidence. And with reliable component partners supporting the ecosystem, industries can build cranes that perform consistently day after day.